TAPPI T 825 Test Fixture

TAPPI T 825 – The flat crush test (1) is a measure of the resistance of the flutes in corrugated board to a crushing force applied perpendicular to the surface

of the board under prescribed conditions.

Please Contact With Us For More Information

- Description

- Reviews (0)

- TECHNICAL SPECIFICATIONS

Description

Description

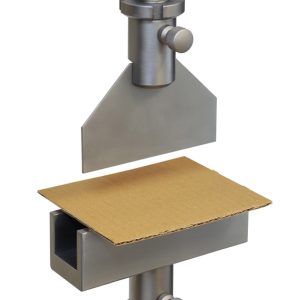

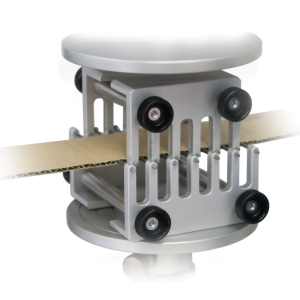

TAPPI T 825 Flat Crush Test of Corrugated Board (Rigid Support Method)

TAPPI T 825 – The flat crush test (1) is a measure of the resistance of the flutes in corrugated board to a crushing force applied perpendicular to the surface

of the board under prescribed conditions.

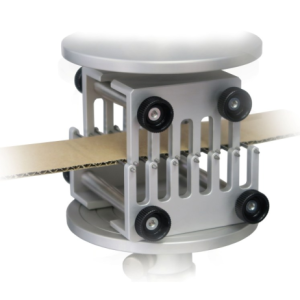

The test is satisfactory for single-faced or single wall (double-faced) corrugated board, but not for double-wall or triple-wall corrugated board, because of lateral

motion of the central facing or facings. In this method the specimen rests on an essentially rigid support and is tested at a constant deflection rate.

See TAPPI T 808 “Flat Crush Test of Corrugated Board” for the procedure in which the specimen rests on a flexing support and is tested at a constant rate of loading.

The test methods do not produce similar results.

TAPPI T 825 – Apparatus

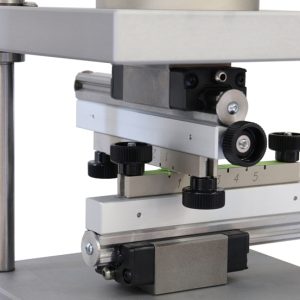

3.1 Compression tester having the following:

3.1.1 A rigidly supported platen and a driven platen, each having a working area of approximately 100 cm2 (about 15.5 in.2 ).

The platens are required to have not more than 0.050 mm (0.002 in.) lateral movement and the rigidly supported platen not more than 0.150 mm (0.006 in.)

movement, perpendicular to the surface, within a load range of 0 to 4500 N (0 to 1000 lbf).

Within a 100 cm2 (15.5 in 2 ) working area each platen shall be flat within 0.0125 mm (0.0005 in.) and the platens shall remain parallel with each other within

1 part in 2000, or 50 μm/100 mm (0.0005 in./in.) throughout the test.

After the platens are checked for parallelism, they may be faced with crocus or emery cloth, free of ridges, by means of double sided tape to prevent slippage.

These facings shall be changed after every 2000 tests.

3.1.2 A means for moving the driven platen to achieve an initial platen separation of at least 60 mm (2.36 in.).

Within a range of platen separation of 0 to 60 mm (0 to 2.36 in.) and within a load range of 0 to 4500 N (0 to 1000 lbf), the speed of the driven platen shall be

controllable at 12.5 ± 0.25 mm (0.50 ± 0.01 in.) per minute.

For convenience, the test machine should be capable of rapid return and automatic, settable positioning.

3.1.3 A capacity of at least 4500 N (1000 lbf).

3.1.4 A means for measuring and indicating the maximum load sustained by the test specimen within 2.2 N(0.5 lbf).

An indicating mechanism that can be checked accurately with dead weight load, load cell, or proving ring.

The accuracy required is 0.5% or 2.2 N (0.5 lbf), whichever is greater.

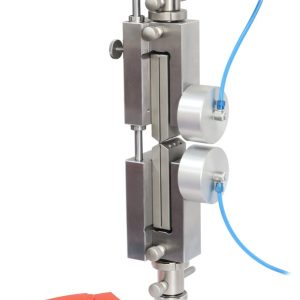

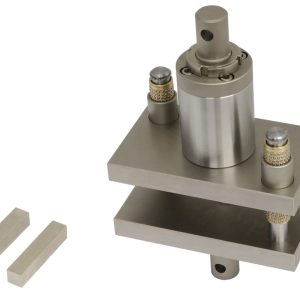

3.2 Specimen cutter, consisting of a device capable of cutting through the corrugated combined board structure without crushing areas at the cut edges.

This may be circular, square, or rectangular.

*** Before conducting TAPPI T 825 , it is important to read the entire specification. Standards can be obtained from appropriate standard authorities.

***PARSROS offers several types of grips and fixtures which will enable you to perform a variety of tests

that are accurate and repeatable.

Reviews (0)

Be the first to review “TAPPI T 825 Test Fixture”

You must be logged in to post a review.

TECHNICAL SPECIFICATIONS

Please Contact with our engineers so that we can find and offer Best Universal Tensile Test Machines , Grips , Jaws and Other Accessories for your operations

Reviews

There are no reviews yet.